fluid coupling

Programs:

Marine propulsion

Mixers

Boat thrusters

Dredges

Supporters & Blowers

Shredders

Compressors

Centrifugal pumps

Recycling equipment

Grinders

Mills

Crushers

Belt conveyors

Wood chippers

Unloaded engine warm up

Clean begin up, no belt slip

Torsional vibration dampening

Shock and overload defense

Higher radial load ability

Distant handle by electric powered valve

Load positioning

Easy to preserve

For in-line and pulley apps

Measurements fifteen â 27

Up to 1340hp

An electrically operated solenoid valve makes it possible for the fluid coupling circuit to be fed when it is turned ON. The  oil drains by way of calibrated orifices positioned on the outer diameter of the fluid coupling. When it is turned OFF, it disengages the motor from the load.

oil drains by way of calibrated orifices positioned on the outer diameter of the fluid coupling. When it is turned OFF, it disengages the motor from the load.

The engine flywheel is related to the KPTO input by a adaptable coupling. The output shaft can be connected to the pushed machine by an elastic coupling, cardan shaft or pulley.

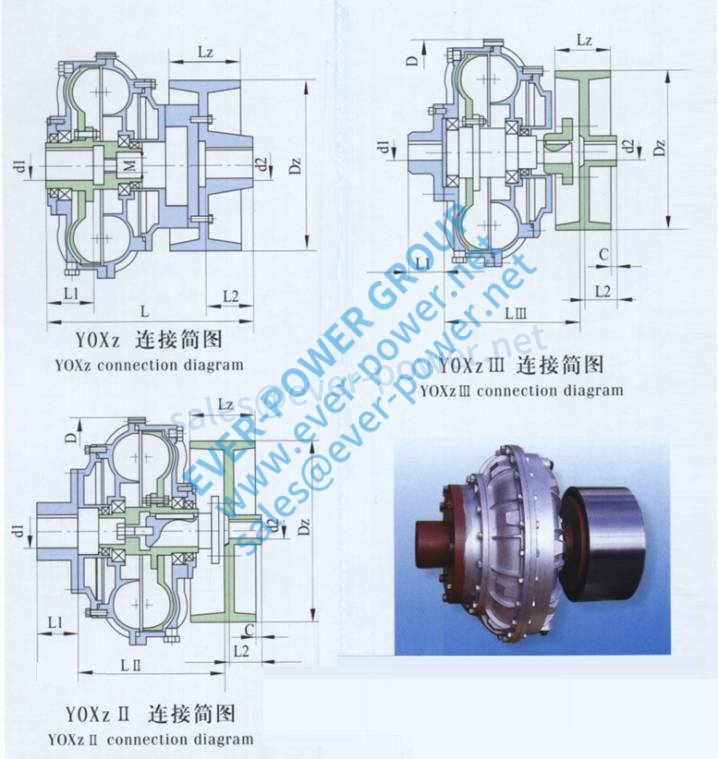

China fluid coupling

KPTO is a variable fill fluid coupling enclosed int o a casing related to the diesel motor by signifies of a SAE housing. The KPTO has been designed to fulfill client specifications combining the technical characteristics of a conventional Energy Get Off with the overall performance of a fluid coupling.

o a casing related to the diesel motor by signifies of a SAE housing. The KPTO has been designed to fulfill client specifications combining the technical characteristics of a conventional Energy Get Off with the overall performance of a fluid coupling.